Decided all the electronics should live in the house, not in the garage.

First step -- Rearrange bedroom to accommodate giant cabinet of electronics.

- First, took everything out of bedroom -- bed, desk, mattress, ...

- I split the desk apart and changed from "L" shape to straight shape after moving bed and desk to at least four configurations in a frenzy of "physical engineering". My usual is careful measurements and graph paper, or once I even tried Sketchup.

- Installed pegboard thingy.

- Installed curtain rods and hung up curtains.

- Installed a new phone jack. I broke the original by dropping a big piece of plywood on it.

- Installed new DSL modem which I got some months ago.

- Fixed my wireless connection, which hasn't functioned for oh so long.

- Installed and wired all the routers and cables and junk into the desk and tidied it all up.

- Moved two file cabinets into place.

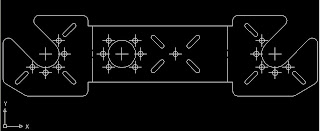

Cleat with crossbars installed in cabinet.

Moved cabinet from garage to apartment with the help of my neighbor. Then actually gathered all the electronics from everywhere and sorted them in the cabinet (somewhat). Also I cleaned the garage while I was at it and got rid of some stuff including a cart that was really in the way. It's great now, I can work in there again. Before, I couldn't get to the workbench. Plus, removing the cabinet means finally a place to put the bandsaw.

The cabinet all put back together.

Contents of cabinet