16 December 2009

The hardware version of "Hello World". Finished final exams today so got some time to do some hacking...

The Gameboy advance controlling an LED via it's serial port, aka Link Cable. Thanks to

avelino herrera morales at http://gba.atlantes.org/index_en.html#hardware for code and schematic.

Gameboy Programming

Sat 3 October 2009

I'm going to use a Gameboy, PSP, Nintendo DS, or somesuch device that includes a display screen, as a remote control for my robots. You'll press buttons on the device, and the software on the device will read the buttons and send commands out to a Zigbee/XBee wireless module. There will be a matching XBee receiver on the robot. My idea is to use this to control Robo-One type walking robots, because they have so many modes/motions/etc. The screen will be used to make a menu to make it easier to select different motions and suchlike.

So... I'm learning to program the Gameboy.

Here is a screenshot of my first program. It moves a crosshairs around on the screen via the Gameboy DPad (directional) buttons. Pretty fun stuff for a fine Saturday morning (if you are a geek, of course).

I'm using the HAM development environment and the VisualBoyAdvance (VBA) emulator running unders Windows XP. I'm learning from this excellent free book: Programming the Nintendo Game Boy Advance, by Jonathan Harbour, www.jharbour.com.

I'm going to use a Gameboy, PSP, Nintendo DS, or somesuch device that includes a display screen, as a remote control for my robots. You'll press buttons on the device, and the software on the device will read the buttons and send commands out to a Zigbee/XBee wireless module. There will be a matching XBee receiver on the robot. My idea is to use this to control Robo-One type walking robots, because they have so many modes/motions/etc. The screen will be used to make a menu to make it easier to select different motions and suchlike.

So... I'm learning to program the Gameboy.

Here is a screenshot of my first program. It moves a crosshairs around on the screen via the Gameboy DPad (directional) buttons. Pretty fun stuff for a fine Saturday morning (if you are a geek, of course).

I'm using the HAM development environment and the VisualBoyAdvance (VBA) emulator running unders Windows XP. I'm learning from this excellent free book: Programming the Nintendo Game Boy Advance, by Jonathan Harbour, www.jharbour.com.

Borders & Templates in Autodesk Inventor

Robot Lives!

Midnight Monday 25 May Memorial Day

Makey Robot moves forward and backward after 10 straight hours of work today.

Makey Robot moves forward and backward after 10 straight hours of work today.

Jeronimo's Mad Science Robot

Elephant is FINISHED

Wed 6 May 2009

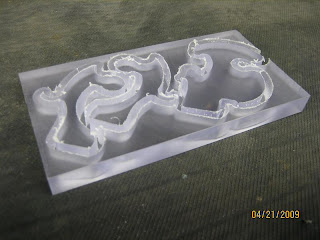

Heffalumps just rule...

Do's and Don'ts

Heffalumps just rule...

Do's and Don'ts

- Don't attempt to make things bigger than the vise. Multiple parts on multiple pieces of stock is a major pain.

- Must leave more than one diameter clearance -- you need 2 diameters or 1.5 diameters

- This means your raw stock is reduced in size by 2 * diameter of the endmill all the way around, in this case, you lose a quarter inch of the entire perimeter of the stock. (1/8" endmill)

- You cannot contour pointy things

- Do not draw radii that are smaller than the endmill

- The radius on all transitions has to end up being greater or equal to the diameter of the endmill

- Don't use a drawing program that exceeds the CAM program you have -- it doesn't understand polylines, splines, etc.

- It's quicker to get another piece of stock and use the manual mill to prepare it to size than it is to spend hours looking at the screen trying to get all the pieces to fit. Rotation is really not quick in CAD.

- It doesn't work well to draw it big and then scale it down, this is where I got into trouble with all the radius problems

- KEY -- To check if the part will be able to be countoured in the CAM program -- here's whatcha do -- you offset it the diameter of the tool. Radii that are too small will fail to offset.

- I think it would have been faster in the end to pick an endmill size, pick a stock size, and draw it freehand in the CAM program.

Just ain't feelin' this tab...

Monday 4 May 2009 4:00PM

... so I ripped it off.

Damn, this thing is strong like a TANK.

Tab was in the way. Couldn't get the batteries or PCB by it. Test-installation of angle brackets.

Things your CAD program didn't tell you... Also totally SUCK is that the 2x2 batteries DON'T FIT because they hit the 4-40 nuts from the motor mount screws. That extra 0.2 inches was supposed to let those batteries fit. So now the motor to move the sensor doesn't fit either, because I lost 1/2" or so to the batteries.

... so I ripped it off.

Damn, this thing is strong like a TANK.

Tab was in the way. Couldn't get the batteries or PCB by it. Test-installation of angle brackets.

Things your CAD program didn't tell you... Also totally SUCK is that the 2x2 batteries DON'T FIT because they hit the 4-40 nuts from the motor mount screws. That extra 0.2 inches was supposed to let those batteries fit. So now the motor to move the sensor doesn't fit either, because I lost 1/2" or so to the batteries.

44 hours of mad science in three days

Bolted motors in and made wheels

Sunday May 3 2009

10:00PM - 2:00 AM

I drilled/filed the mounting holes for the motors and got the motors bolted in.

I then used the LEGO rims and tires and drilled the hubs to mate with the LEGO. BUT, it didn't work, because the nut sticks out too far. Solution would be to tap threads into the hub. BUT, I already drilled the hole too big, plus, I don't have an 8-32 tap.

And, I'm on a mission to GET THE WHEELS ON at all costs, SO, I made different wheels.

I made wheels out of wood using a hole saw.

10:00PM - 2:00 AM

I drilled/filed the mounting holes for the motors and got the motors bolted in.

I then used the LEGO rims and tires and drilled the hubs to mate with the LEGO. BUT, it didn't work, because the nut sticks out too far. Solution would be to tap threads into the hub. BUT, I already drilled the hole too big, plus, I don't have an 8-32 tap.

And, I'm on a mission to GET THE WHEELS ON at all costs, SO, I made different wheels.

I made wheels out of wood using a hole saw.

Calliope PCB Works the First Time

HOT DAMN!!!

Sunday 3 May 9 PM

Applied power to PCB and away it went, playing a tune...

Sunday 3 May 9 PM

Applied power to PCB and away it went, playing a tune...

Built robot body

Final Virtual Model of Robot

Virtual Assembly

Better Bodies

Robot Design Day 2

Learned to BEND METAL !!!!!!!!!

Friday May 1 - Afternoon

I am so stoked!! Bruce from Dorkbots showed me how to use the finger brake to make a metal box! Evil cackle, rub hands with glee, I am now the master of the universe, bwahahaha! He's created a monster. This means that I can MAKE ROBOT BODIES really easily! Really nice ones. I am so stoked. I have been puzzling over the mysteries of sheet metal for many moons and along comes this really nice guy and not only shows me how to do it, but actually has the patience to actually stand around while I fumble through the entire process!! Wow! Thanks a zillion, Bruce, I owe 'ya. And thanks to Steamboat Ed and his freakin' fantabulous shop.

Here is the box I made.

Tools: Shear, notcher, Whitney punch, finger brake.

This is so awesome I am inclined to create a Instructable or something showing others how to achieve this miraculous result. Well, perhaps if I lie down for a while, the urge will pass.

I am so stoked!! Bruce from Dorkbots showed me how to use the finger brake to make a metal box! Evil cackle, rub hands with glee, I am now the master of the universe, bwahahaha! He's created a monster. This means that I can MAKE ROBOT BODIES really easily! Really nice ones. I am so stoked. I have been puzzling over the mysteries of sheet metal for many moons and along comes this really nice guy and not only shows me how to do it, but actually has the patience to actually stand around while I fumble through the entire process!! Wow! Thanks a zillion, Bruce, I owe 'ya. And thanks to Steamboat Ed and his freakin' fantabulous shop.

Here is the box I made.

Tools: Shear, notcher, Whitney punch, finger brake.

This is so awesome I am inclined to create a Instructable or something showing others how to achieve this miraculous result. Well, perhaps if I lie down for a while, the urge will pass.

Balloon Popping LEGO Robot

Programmed Hardware

Thursday Night after work April 20 2009

Ha! Programmed all three circuits and they pretty much worked the first time. Can I wire, or what? Presented to Steamboat Ed at the Dorkbots meeting, and we decided to go with the thumbwheel, or DigiSwitch, whatever you call it. These things are my new favorite input device.

Ha! Programmed all three circuits and they pretty much worked the first time. Can I wire, or what? Presented to Steamboat Ed at the Dorkbots meeting, and we decided to go with the thumbwheel, or DigiSwitch, whatever you call it. These things are my new favorite input device.

Wired prototype circuits

Tuesday night 28 April 2009

Finished wiring up 3 test circuits for next version of Steamboat Ed's Calliope. Total time = 4 hours.

DIP Switches - Use DIP switches to select songs - practice your binary numbers. Steamboat's idea -- but let's give him some more options...

Thumbwheel - My Favorite - Just dial in the song number you want

Up Down Button with 7-Segment LED Display - Push up or down to increment/decrement song number. Song number will display on 7 segment LEDs. (2 digits)

Damn good fun.

Next step - programming.

Finished wiring up 3 test circuits for next version of Steamboat Ed's Calliope. Total time = 4 hours.

DIP Switches - Use DIP switches to select songs - practice your binary numbers. Steamboat's idea -- but let's give him some more options...

Thumbwheel - My Favorite - Just dial in the song number you want

Up Down Button with 7-Segment LED Display - Push up or down to increment/decrement song number. Song number will display on 7 segment LEDs. (2 digits)

Damn good fun.

Next step - programming.

lost parts OH SO FRUSTRATING

Saturday 25 April 2009

I have lost the *@#! slide spring for my carburetor. Looked everywhere and even went back to work to see if I left it there. Can't figure out how a four inch spring could go missing.

Well, other than that SLIGHT detail, it's reassembled.

I have lost the *@#! slide spring for my carburetor. Looked everywhere and even went back to work to see if I left it there. Can't figure out how a four inch spring could go missing.

Well, other than that SLIGHT detail, it's reassembled.

LEGO robotics - whittling down our time

Friday 24 April 2009

Worked on LEGO robot for "Pit of Despair" contest. Or I should say, watched Jeronimo work on the robot. 'Cause he's the man. 10-4 or so. Knocked some hella time off, we got like ah twenty seconds faster through the Pit of Despair.

Worked on LEGO robot for "Pit of Despair" contest. Or I should say, watched Jeronimo work on the robot. 'Cause he's the man. 10-4 or so. Knocked some hella time off, we got like ah twenty seconds faster through the Pit of Despair.

moto/metal/PCB

Puzzle pieces at last

Fail Puzzle

Makin' Bolts

Sunday April 19, 2009

Worked on my motorcycle. Hasn't run in 2 years. Bought/charged/installed battery, then started working on the rear brake mounting.

Somehow these bolts went missing and I need them for my motorcycle. Was going to order the proper thing and then it occurred to me I could "make do" by chopping off and then drilling a hole in a similar bolt. Need two bolts with particular shoulder and hole drilled for a cotter pin.

Motorcycles are particular, boy oh boy, the shoulder on the bolt fits exactly width wise and length into the brake drum bracket. So, it's NOT a permanent fix, and boy my old boss Charlie Craig would NOT approve :)

Before - Proper bolt in foreground, donor bolt in background

After - Hacksawed and drilled and looks pretty close, though shoulder diameter is too small.

Installed on the bike (photo only shows one of them).

Worked on my motorcycle. Hasn't run in 2 years. Bought/charged/installed battery, then started working on the rear brake mounting.

Somehow these bolts went missing and I need them for my motorcycle. Was going to order the proper thing and then it occurred to me I could "make do" by chopping off and then drilling a hole in a similar bolt. Need two bolts with particular shoulder and hole drilled for a cotter pin.

Motorcycles are particular, boy oh boy, the shoulder on the bolt fits exactly width wise and length into the brake drum bracket. So, it's NOT a permanent fix, and boy my old boss Charlie Craig would NOT approve :)

Before - Proper bolt in foreground, donor bolt in background

After - Hacksawed and drilled and looks pretty close, though shoulder diameter is too small.

Installed on the bike (photo only shows one of them).

Jank Mechanic's Rolling Chair

BinkyBot

Saturday March 18 2009

Now that the great electronic reorg is complete, I can have some fun actually doing electronics. I did a rebuild on an old robot which I made back in 2001. The breadboard was torn up so I rewired and reprogrammed it. This is maybe the second robot I built from scratch. I have maybe one or two more robots like this that I would like to get running again.

Now that the great electronic reorg is complete, I can have some fun actually doing electronics. I did a rebuild on an old robot which I made back in 2001. The breadboard was torn up so I rewired and reprogrammed it. This is maybe the second robot I built from scratch. I have maybe one or two more robots like this that I would like to get running again.

Robot in disrepair.

Where old robot code lives.

This is my old computer, a Toshiba Libretto. Still works and was able to plug right in and program this robot.

Now that the great electronic reorg is complete, I can have some fun actually doing electronics. I did a rebuild on an old robot which I made back in 2001. The breadboard was torn up so I rewired and reprogrammed it. This is maybe the second robot I built from scratch. I have maybe one or two more robots like this that I would like to get running again.

Now that the great electronic reorg is complete, I can have some fun actually doing electronics. I did a rebuild on an old robot which I made back in 2001. The breadboard was torn up so I rewired and reprogrammed it. This is maybe the second robot I built from scratch. I have maybe one or two more robots like this that I would like to get running again.Robot in disrepair.

Where old robot code lives.

This is my old computer, a Toshiba Libretto. Still works and was able to plug right in and program this robot.

BigTrak

13 April 2009

Fixed up someone's BigTrak at work. This toy rocks, it's programmable. You use the keypad to enter distance and direction and it can execute 16 motions/actions in a row.

Cleaned battery connections with baking soda, glued axle back together (ok coworker did the glueing), battery connector for trailer broke so had to sort of solder weld it back together.

Fixed up someone's BigTrak at work. This toy rocks, it's programmable. You use the keypad to enter distance and direction and it can execute 16 motions/actions in a row.

Cleaned battery connections with baking soda, glued axle back together (ok coworker did the glueing), battery connector for trailer broke so had to sort of solder weld it back together.

The Great Electronics Reorg of 2009

March 30 - April 18, 2009

Decided all the electronics should live in the house, not in the garage.

First step -- Rearrange bedroom to accommodate giant cabinet of electronics.

Cleat with crossbars installed in cabinet.

Moved cabinet from garage to apartment with the help of my neighbor. Then actually gathered all the electronics from everywhere and sorted them in the cabinet (somewhat). Also I cleaned the garage while I was at it and got rid of some stuff including a cart that was really in the way. It's great now, I can work in there again. Before, I couldn't get to the workbench. Plus, removing the cabinet means finally a place to put the bandsaw.

The cabinet all put back together.

Contents of cabinet

Decided all the electronics should live in the house, not in the garage.

First step -- Rearrange bedroom to accommodate giant cabinet of electronics.

- First, took everything out of bedroom -- bed, desk, mattress, ...

- I split the desk apart and changed from "L" shape to straight shape after moving bed and desk to at least four configurations in a frenzy of "physical engineering". My usual is careful measurements and graph paper, or once I even tried Sketchup.

- Installed pegboard thingy.

- Installed curtain rods and hung up curtains.

- Installed a new phone jack. I broke the original by dropping a big piece of plywood on it.

- Installed new DSL modem which I got some months ago.

- Fixed my wireless connection, which hasn't functioned for oh so long.

- Installed and wired all the routers and cables and junk into the desk and tidied it all up.

- Moved two file cabinets into place.

Cleat with crossbars installed in cabinet.

Moved cabinet from garage to apartment with the help of my neighbor. Then actually gathered all the electronics from everywhere and sorted them in the cabinet (somewhat). Also I cleaned the garage while I was at it and got rid of some stuff including a cart that was really in the way. It's great now, I can work in there again. Before, I couldn't get to the workbench. Plus, removing the cabinet means finally a place to put the bandsaw.

The cabinet all put back together.

Contents of cabinet

Subscribe to:

Comments (Atom)